Accessories

Accessories for professional floor polishers. Diamond tool and high quality utensils.

In the world of floor polishing and polishing, diamond tools and polishing tools play a key role. They are designed to provide the highest level of polish and shine on all types of materials, from metals to natural stones such as marble, terrazzo and granite. These tools combine diamond and polishing powder to achieve exceptional results in the polishing and polishing process.

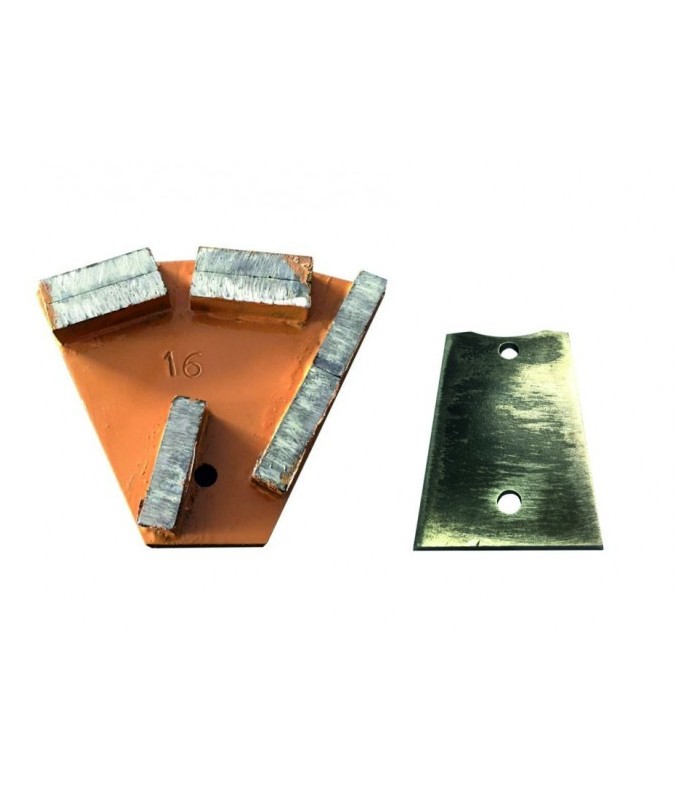

Metal diamond tools and their use in roughing hard surfaces

Metal diamond tools are essential in the roughing process of hard surfaces. Their specific composition and design allow them to work effectively on resistant materials such as granite and marble.

Features of Metal Diamond Tools

- They are composed of polycrystal-encrusted pads, which gives them a high capacity for wear on hard surfaces.

- Their design ensures exceptional durability, making them long-life tools.

- They are ideal for the initial roughing of surfaces before polishing and polishing.

Applications of metal tools in the polishing of natural stones

Metal diamond tools are widely used in the natural stone polishing industry. Their ability to roughen hard surfaces such as granite makes them indispensable in processes where it is necessary to eliminate imperfections and achieve a smooth base for subsequent polishing.

Resin diamond tools for satellite polishers

Resin diamond tools are an essential element in the process of polishing and polishing surfaces with satellite polishers. They are characterized by their ability to provide a fine finish and enhance the color of surfaces, achieving exceptional results in materials such as marble, terrazzo and granite.

Features of Resin Tools

- Combines diamond and brightening powder

- Specially designed for satellite polishers

- Provide a fine, glossy finish

Applications of Resin Tools

Resin tools are used to enhance the color and brightness of natural stone surfaces, such as marble, terrazzo, and granite. They are ideal for obtaining exceptional results in the polishing and polishing process, improving the appearance of all types of materials.

Machinery used in the polishing and polishing process

Traditional polishing and polishing machines

Traditional polishers and polishers play a key role in the polishing and polishing process of all types of surfaces. Its main function is to work efficiently on marble, terrazzo and granite floors, providing a high-quality finish.

Satellite polishing machines

On the other hand, satellite polishers are ideal for polishing and polishing large surfaces quickly and efficiently. These machines allow you to work in large spaces, providing exceptional results in terms of gloss and final finish.

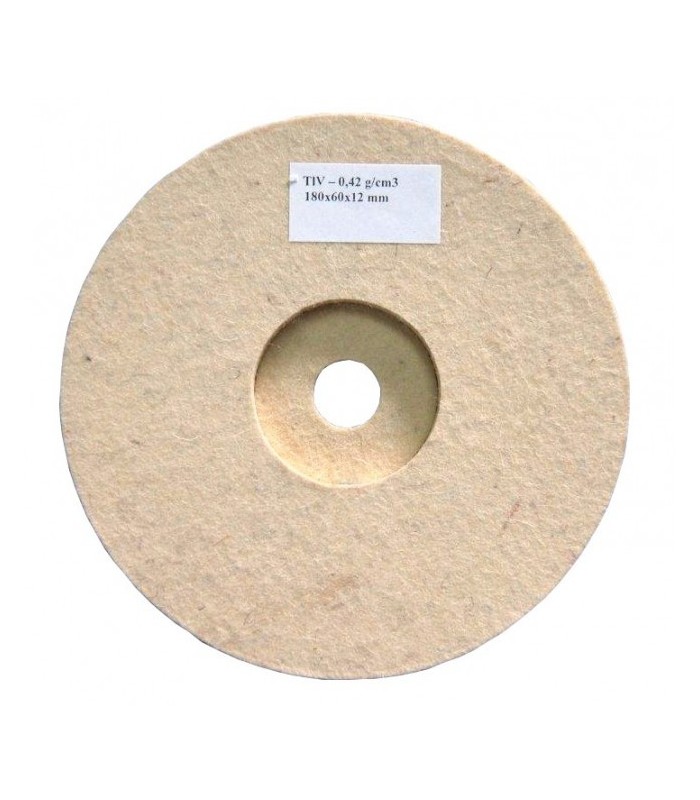

Fibre discs to complement polishing work

Fibre discs are essential tools in the polishing process, providing efficient daily cleaning and maintenance on various surfaces. Their versatility and efficiency make them indispensable allies to achieve high-quality polished finishes.

Uses and Advantages of Fiber Discs in Daily Cleaning and Maintenance

- Effective removal of residues and surface dirt.

- Smooth polishing that does not damage the treated surface.

- Designed to be compatible with different types of polishing machines.

- They help maintain the shiny appearance of polished surfaces in good condition.

Application of Onyx fibre discs for the highest quality polishing

- Onyx fibre discs are ideal for applying hard waxes and obtaining exceptional shine on treated surfaces.

- Its special composition ensures uniform and high-quality polishing with each use.

- Suitable for all types of natural stones and sensitive materials.

Surface polishing chemicals

Chemicals play a crucial role in the surface polishing process, providing different benefits depending on their composition and application. The functions of these fundamental elements in the polishing process are detailed below:

Crystallizers and vitrifiers

- Crystallizers and vitrifiers are specially designed to provide a high level of gloss on various types of floors, standing out for their ability to restore and protect surfaces.

- These chemicals work by filling in small imperfections on the surface, creating a protective layer that enhances the natural shine of the materials.

Abrasives such as crowns and sandpaper

- Crowns and sandpapers are essential for roughing and polishing natural stone surfaces, allowing irregularities to be eliminated and a smooth and shiny finish to be achieved.

- These abrasives are used in combination with specialized machinery to ensure effective and uniform polishing on different types of surfaces.

Exceptional results in the polishing and polishing process

In the polishing and polishing process, the right combination of machinery, discs and chemicals is key to obtaining professional and glossy finishes on all types of surfaces. The quality of the products offered plays a critical role in obtaining exceptional results.

Benefits of using high-quality tools

- High-quality diamond tools and utensils have a direct impact on the final polishing result, ensuring a superior finish.

- Investing in high-end polishing materials and machinery results in more efficient and long-lasting results in the stone polishing and polishing process.

Impact of diamond tools and utensils on the bottom line

Metal and resin diamond tools, along with the right fiber discs and chemicals, are critical to achieving exceptional polish and flawless shine on marble, granite, and natural stone surfaces.

Features of Metal Diamond Tools

- Metal diamond tools are designed for roughing hard and resistant surfaces, offering optimal performance in the polishing process.

- With polycrystal-encrusted tablets, these tools ensure uniform and efficient roughing on all types of materials.

Applications of metal tools in the polishing of natural stones

- Metal diamond tools are ideal for roughing and polishing natural stones such as marble, terrazzo and granite, providing a fine and shiny finish.

- Its use in traditional and satellite polishing machines allows the color and texture of surfaces to be enhanced, achieving exceptional results in the polishing process.

Advantages of Using High-Quality Tools in Stone Polishing

Impact of diamond tools and utensils on the bottom line

The quality of the diamond tools and utensils used in the stone polishing process has a direct impact on the final result of the work. High-quality tools ensure uniform polishing, with precise, glossy finishes that enhance the natural beauty of the surfaces.

Benefits of Investing in High-End Polishing Materials and Machinery

- Increased efficiency: High-quality tools allow polishing to be carried out more efficiently, reducing working time and increasing productivity.

- Durability: By investing in high-end tools, their durability and resistance are guaranteed, which translates into less wear and longer material life.

- Superior Finishes: High-quality tools offer superior finishes in stone polishing, with professional, high-precision results that meet customer expectations.

- Cost reduction: Despite the initial investment, using high-quality tools can help reduce costs in the long run, by minimizing the need for frequent replacement and getting higher-quality work done in less time.

Investing in high-end polishing materials and machinery brings numerous benefits for professionals in the marble, granite and natural stone industry. The use of quality tools guarantees exceptional results and professional finishes on all types of surfaces.

Novelda abrasives at the service of floor polishing and polishing companies

Highlighting the quality of the products offered

At Novelda Abrasives, we pride ourselves on offering the highest quality products to ensure exceptional results in the stone polishing and polishing process. Our diamond tools and polishing tools are designed to provide a flawless, long-lasting finish on all types of surfaces.

Commitment to innovation and excellence

- Our products are the result of years of research and development in the field of floor polishing, ensuring the incorporation of the latest cutting-edge technologies and materials.

- We work closely with reputable manufacturers to ensure the quality and effectiveness of every tool and utensil we offer.

Commitment to good service and customer satisfaction

In our company, a commitment to customer satisfaction is paramount. We strive to provide personalized service and exceptional attention to every professional in the marble, granite, and natural stone industry who trusts us to acquire their polishing tools.

Dedicated customer service team

- Our customer service team is highly trained to provide technical advice and resolve any doubts or concerns that may arise during the purchase process.

- We are committed to providing a fast and efficient service, ensuring the timely delivery of all orders and the personalized attention that each customer deserves.