Beaved hammered and sandblasted for finishes

BUSH-HAMMERING AND SANDBLASTING FOR FINISHES: A GUIDE FOR MARBLE AND NATURAL STONE PROFESSIONALS

Bush-hammering and sandblasting are common techniques in natural stone finishing, improving its aesthetics and durability. These processes create specific textures and functional properties in various architectural applications. Specialized machinery and technical know-how enable high-quality results in the marble and natural stone industry.

Most common types of stone and finishes

In the bush-hammering and sandblasting process, it is essential to know the different types of stone and the most common finishes that can be achieved. The following are the main characteristics of the stones that can be bush-hammered and sandblasted:

Bush-hammerable stones

- Granites: This natural stone lends itself very well to bush-hammering, as it allows it to create a rough and glassy texture that enhances its natural beauty.

- Slates: Slates are another common choice for bush-hammering, as this finish brings out their natural tones and provides anti-slip properties.

- Sandstones: The porous texture of sandstones makes them ideal candidates for bush-hammering, improving both their appearance and strength.

Sandpable stones

- Marbles: Sandblasting is especially effective on marbles, as it enhances their natural colors and provides a smooth and elegant texture.

- Granites: Granites can also be sandblasted, creating a slightly more colorful and smooth finish than traditional bush-hammering.

- Sandstones: As with bush-hammering, sandstones benefit from sandblasting, highlighting their natural beauty and improving their strength.

Comparison of finishes in different types of natural stone

When analyzing the application of bush-hammering and sandblasting on different types of natural stone, it is observed how each finish highlights the unique qualities of each material. The choice between bush-hammered and sandblasted will depend on the desired aesthetic effect and the functional properties sought in the stone.

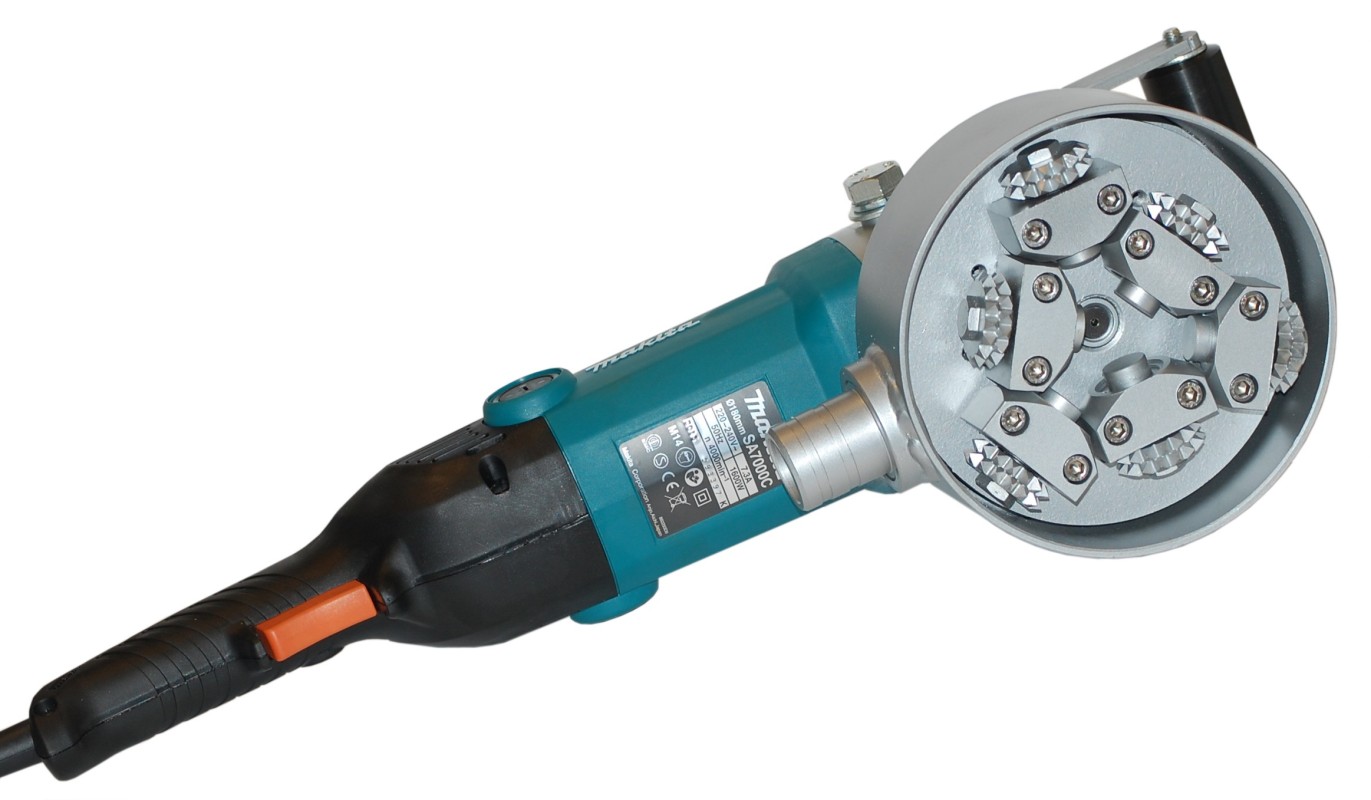

Bush-hammering and sandblasting machinery and tools

The machinery and tools used in bush-hammering and sandblasting natural stone are essential to obtain high-quality and durable results. The different elements necessary to carry out these processes are detailed below:

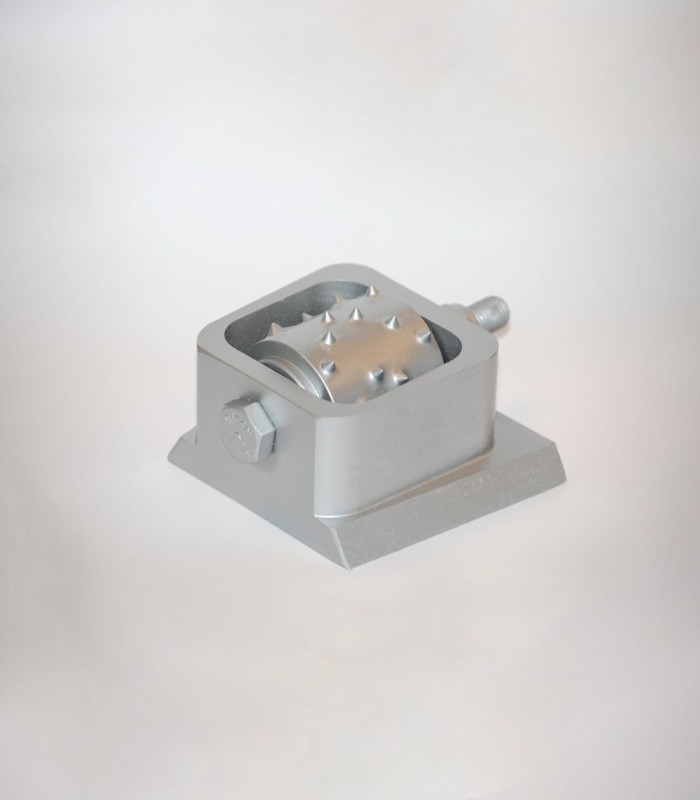

Specific tools for bush-hammering

- Bush-hammers of different sizes and shapes to create the characteristic craters in the stone.

- Striping rollers that allow for uniform and controlled bush-hammering.

- Pneumatic hammers to hit the surface of the stone with precision.

Machinery Needed for Sandblasting

- High-pressure silica or corundum sand spraying equipment.

- Air compressors to generate the necessary pressure in the sandblasting process.

- Sandblasting booth to contain and recycle the sand used in the process.

Combining techniques and tools for optimal results

- The combination of bush-hammered and sandblasted can achieve unique and customized finishes on the stone.

- It is important to select the right tools and machinery for each type of stone and desired finish.

- The precision in the use of tools and technique provide a quality and durable finish.

Aesthetic and functional advantages of stone finishes

Bush-hammering and sandblasting offer a variety of advantages both in aesthetic and functional terms for natural stone used in architectural applications. The main advantages of these finishes are detailed below:

Improved aesthetic appearance

- Creation of rough and eye-catching textures that enhance the natural beauty of the stone.

- Accentuation of the colors and veins of the stone, highlighting its visual appeal in different environments.

- Possibility of customizing the finish to adapt it to various architectural styles and aesthetic preferences.

Increased strength and durability of the stone

- Generation of a surface layer that is more resistant to abrasion and atmospheric agents, prolonging the useful life of the stone.

- Increased slip resistance on surfaces exposed to wet or slippery conditions.

- Improved ability of the stone to resist impacts and shocks, maintaining its original appearance for longer.

Anti-slip properties and other functional advantages

- Creation of surfaces with non-slip properties, ideal for areas with high pedestrian or vehicular traffic.

- It helps prevent accidents and slips by providing greater traction and grip on floors and pavements.

- It facilitates the maintenance and cleaning of bush-hammered and sandblasted surfaces, maintaining their original appearance with ease.

Architectural Applications and Use Cases

Bush-hammering and sandblasting are used in various architectural applications to enhance the natural beauty of stone and enhance its functional properties. Significant examples of use in different contexts are presented below:

Façade cladding

- Revitalization of historic buildings with bush-hammered stones such as granite to highlight their traditional character.

- Sandblasting modern skyscraper facades to create smooth, uniform textures that elegantly reflect light.

Floors and pavements

- Application of bush-hammered work on outdoor floors to provide anti-slip resistance, ideal for areas with high pedestrian traffic.

- Sandblasting on interior floors of commercial spaces to highlight aesthetics and facilitate surface maintenance.

Other uses in architecture

- Decorative details on stairs, achieving combinations of textures in marble and granite for a unique look.

- Finishes on kitchen countertops, such as bush-hammered slates, to add a natural and functional touch to gourmet spaces.

These examples illustrate the versatility and effectiveness of bush-hammering and sandblasting in various architectural applications, providing aesthetic and functional value to the spaces where they are used.

Final considerations and recommendations for professionals

At the end of the bush-hammering and sandblasting process, it is crucial to take into account a series of recommendations that contribute to optimizing the final results and ensuring customer satisfaction. Here are some final considerations and recommendations for professionals:

Care and maintenance of bush-hammered and sandblasted surfaces

- Perform periodic cleaning with gentle products to preserve the texture and color of the stone.

- Avoid the use of abrasive products that may damage the bush-hammered or sandblasted surface.

- Apply specific sealants for natural stone to protect it from stains and external agents.

Tips for choosing the right finish

- Consider the type of stone and its end use to select between bush-hammered, sandblasted or other available finishes.

- Pay attention to the required anti-slip properties based on the location of the surface.

- Request samples of finishes to evaluate how they integrate with the overall design of the project.

Innovations and trends in natural stone finishes

- Explore new techniques and technologies to offer innovative and exclusive finishes to customers.

- Be aware of trends in design and architecture that may influence the choice of stone finishes.

- Participate in trade fairs and events in the sector to learn first-hand about the latest developments in natural stone finishes.

Contact and service of Segments Frankfurt for professionals in the sector

Quality abrasive tools catalogue

At Segments Frankfurt, we offer an extensive catalog of high-quality abrasive tools, specifically designed for the polishing of natural stone surfaces such as marble and granite. Our segments are critical to achieving exceptional results in stone finishing.

Personalized service and technical advice

We stand out for providing a personalized service to each professional in the marble and natural stone industry who trusts our products. Our technical team is highly trained to offer specialized advice and solve any queries or technical needs.

Commitment to excellence and customer satisfaction

At Segments Frankfurt, our main commitment is excellence in the quality of our products and the full satisfaction of our customers. We work every day to exceed expectations and ensure outstanding results in every application of our abrasive segments.