Portable Bushguards

PORTABLE BUSH HAMMERS: A Guide for Marble and Natural Stone Professionals

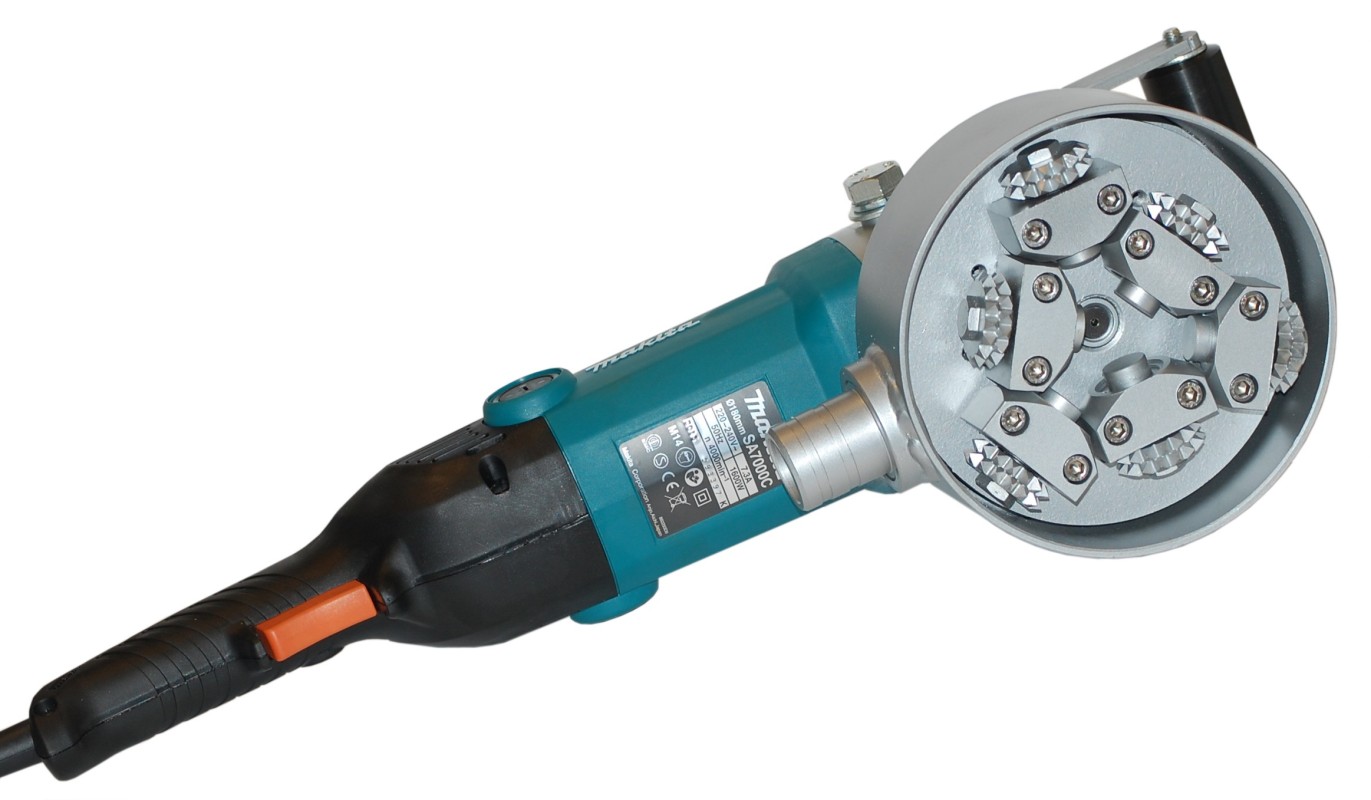

Portable bush hammers are versatile and practical tools for bush-hammering various materials such as marble, granite and concrete. They allow fine, medium or coarse finishes, as well as sandblasting and scratching. They are easy to transport and can be used on different vertical and horizontal surfaces, such as stairs, steps and walls. There are different models on the market adapted to different jobs, with features such as speed regulation and a variety of rollers.

Features of portable bush hammers

Portable bush hammers are specialized tools that offer various features that make them ideal for bush-hammering a wide range of materials efficiently and accurately. Here are some of the main characteristics they usually have:

Speed regulation and protection

- They allow you to adjust the bush-hammering speed according to the needs of the job.

- They have protection mechanisms to guarantee the safety of the user during their use.

Different types of rollers

- They offer a variety of rollers to achieve different finishes, such as fine, medium or coarse bush-hammering.

- Rollers of different sizes allow different surface finish thicknesses to be achieved.

Front handle and suction socket

- The front handle makes it easy to operate and control the tool during use.

- The suction socket helps to keep the work area clean and dust-free.

Applications and advantages on different surfaces

Portable bush hammers are versatile tools that offer numerous applications and advantages when bushing various surfaces. Below are the main applications and benefits they offer in different contexts:

Horizontal and vertical work

Portable bush hammers stand out for their ability to perform work on both horizontal and vertical surfaces, making them versatile and useful tools in a wide range of work scenarios. This feature allows you to cover different types of projects, from bush-hammering stairs and steps to creating precise finishes on walls and walls.

Surfaces where they can be used

- Walls and walls of different materials such as marble, granite, limestone, concrete and artificial stone.

- Columns, stairs and steps, offering a range of possibilities for the application of bush-hammered finishes.

- Access ramps and other horizontal surfaces that require special treatment to ensure safety and aesthetics.

Paint removal on various materials

In addition to their primary function of bush-hammering and providing textured finishes, some portable bush hammers can also be used for paint removal on a variety of surfaces, such as swimming pools, walls, and floors. This versatility makes these tools indispensable allies in restoration and renovation work, guaranteeing professional and high-quality results.

Types of Portable Bush-Hammers on the Market

Models with height-adjustable guides

Portable bush hammers with height-adjustable guides offer the possibility of adjusting the depth and height of the bush-hammer precisely, which is essential for jobs that require a specific finish. These tools allow you to adapt to different material thicknesses and surfaces, making it easier to create quality non-slip strips.

Equipped with various plates and rollers

Portable bush hammers equipped with a variety of plates and rollers allow different thicknesses and finishes to be achieved on the bush hammered surface. The diversity of options of these elements facilitates the versatility of the tool, adapting to different bush-hammering needs and guaranteeing professional results on a wide range of materials.

Tailored to specific jobs

There are portable bush hammers designed for specific jobs, such as creating particular finishes on certain materials or surfaces. These tools have specialized features that make them ideal for custom tasks, ensuring efficiency and accuracy in every application.

Correct use and maintenance of tools

Importance of proper training

Proper training in the use of portable bush hammers is essential to ensure safe and efficient handling of these tools. Learning the correct techniques and the necessary safety measures will help to avoid accidents and optimise the results in bush-hammering of different materials.

Care to ensure durability and efficiency

- Perform regular maintenance: It is important to carry out regular checks on the bush hammers to detect possible failures or wear in the components.

- Proper cleaning: After each use, it is advisable to carefully clean the tool to remove material residues and ensure optimal operation in future applications.

- Correct storage: Storing the bush hammers in a dry and safe place, away from moisture and possible shocks, will help to prolong their useful life.

Recommendations for correct management

In addition to receiving the appropriate training, it is important to follow some key recommendations for the proper handling of portable bush hammers:

- Always wear personal protective equipment, such as gloves, goggles, and appropriate footwear, to prevent possible injuries during use.

- Respect the manufacturer's instructions regarding the operating speed and the types of rollers to be used, to ensure effective and safe bush-hammering.

- Avoid forcing the tool on the material to be bush-hammered, allowing the machine to carry out the work in a smooth and controlled way.

Comparison of brands and specialized manufacturers

Diversity of models and options available

In today's market, there are a wide variety of brands and manufacturers specialized in portable bush hammers, each offering different models and options adapted to the needs of professionals in the sector. This diversity of offerings allows users to select the tool that best fits their type of work and specific requirements.

Factors to Consider When Choosing a Tool

- Quality of materials: It is essential to ensure that the tool is made from durable and resistant materials to ensure optimal performance over time.

- Additional functionalities: Some portable bush hammers may have extra features, such as speed regulation or specific types of rollers, which can influence the efficiency and versatility of the tool.

- Accessory compatibility: It is important to check if the chosen model is compatible with additional accessories that can facilitate certain types of jobs or specific applications.

Tips for selecting the best option

When choosing a portable bush hammer, it is advisable to make a detailed comparison between the different brands and manufacturers available on the market. Considering aspects such as the manufacturer's reputation, the warranty offered, the opinions of other users, and the value for money can be key to making the best decision based on the particular needs of each professional.

Achieving professional and high-quality finishes

To achieve professional and high-quality finishes in bush-hammering of different materials, it is essential to take into account the importance of the choice and correct handling of tools. Here are some tips for optimal results and key aspects to consider for successful work:

Importance of the correct choice and handling of tools

- Select the right portable bush hammer for the type of material and the desired finish.

- Make sure to adjust the speed and pressure optimally for each surface.

- Keep the tool in good condition and perform regular maintenance to ensure its efficiency.

Tips for optimal results

- Practice on a test surface before starting the main job.

- Make uniform and controlled movements to obtain a homogeneous finish.

- Use suitable rollers and plates to achieve the desired finish thickness.

Things to consider for a successful job

- Work in a properly ventilated environment and with the necessary safety measures.

- Follow the manufacturer's instructions for the use and maintenance of the tool.

- Regularly inspect the bush-hammered surface to ensure the quality of the finish.