Diamond Tools

Diamond Tools for Professional Polishing of Marble, Granite and Terrazzo: Innovation and Efficiency

Diamond tools are essential for professional polishing of marble, granite and terrazzo. Its specialized design allows for high-quality finishes on hard surfaces, improving work efficiency. This article will address various aspects of these tools, including their types, advantages, and techniques of use. In addition, applications in different sectors will be explored, as well as innovations that have emerged in this field.

What are diamond tools?

Diamond tools are equipment specifically designed to work with hard surfaces, such as marble, granite, and terrazzo. Its use has transformed the cutting and polishing process, optimizing the results and efficiency of the work.

Concept and Definition

Diamond tools are devices that incorporate industrial diamonds into their structure, making them the most effective for carrying out cutting and polishing operations on difficult materials. These tools are used both in construction and in the restoration of surfaces, guaranteeing high quality finishes. Diamonds' ability to scorch and make precise cuts makes them essential in a variety of industrial surface treatment processes.

Materials Used

The construction of diamond tools is based on a combination of materials that provide strength and durability. The main components are:

- Industrial Diamonds: They act as the main abrasive element, allowing effective cuts and polishes.

- Soft Metals: They are used in the base of tools to facilitate the union of elemental diamons. These metals allow the abrasive segments to remain attached during use.

- Resins: In some tools, resins are used to improve the flexibility and adaptability of the tool, favoring its use on different machines and surfaces.

Types of Diamonds Used

There are different types of diamonds that are used in the manufacture of diamond tools. Each of them has specific characteristics that make them more or less suitable for various applications:

- Synthetic Diamonds: Generally cheaper, they are produced in the laboratory and offer uniformity in their quality. They are widely used in industrial applications.

- Natural Diamonds: Although they are more expensive, they are used for their exceptional hardness. They are ideal for situations where superior performance is required.

- Polycrystalline Diamonds: Composed of multiple diamond crystals, they are highly effective for cutting and polishing very hard materials, such as certain types of granite.

Advantages of Using Diamond Tools in Polishing

Diamond tools offer a number of significant benefits that transform the process of polishing hard surfaces. Their effectiveness and the finish obtained make them a preferred choice in the sector.

Durability

One of the main advantages of diamond tools is their exceptional durability. These tools are made of high-strength materials, which allows them to withstand intensive use without losing effectiveness. This durability translates into:

- Fewer replacements needed, reducing operating costs.

- Longer service life compared to conventional tools, which optimizes the initial investment.

- Reduced risk of failures during operation, ensuring continuous and uninterrupted work.

Machine Versatility

Diamond tools are highly versatile and can be used on a wide variety of machines. This feature allows professionals to work on different types of projects without having to constantly switch teams. Some of the advantages of this versatility include:

- Compatibility with traditional polishers, satellites and planetary systems.

- Ability to adjust the type of tool to specific job needs.

- Ease of installation and use on different devices, which expands its applicability in the sector.

High Quality Finish

The quality of the finish is another crucial factor in surface polishing. Diamond tools are known for providing a superior finish, characterized by:

- Smooth and shiny surfaces that enhance the aesthetics of the treated material.

- Reduction of marks and defects, which translates into more professional work.

- Ability to carry out finishes of different grades, adapting to the needs of the client.

Work Efficiency

The use of diamond tools also increases efficiency during the polishing process. This is due to several reasons:

- Less time needed to complete polishing tasks compared to traditional tools.

- Ability to perform multiple steps in a single process, streamlining workflow.

- Reduced dust and waste, making cleaning easier and reducing downtime.

Types of Diamond Tools

Diamond tools are essential in the process of polishing and cutting hard surfaces. There are several types that adapt to different needs and techniques, each with specific characteristics that allow them to perform precise and efficient tasks.

Diamond crowns

Diamond crowns are tools designed primarily for drilling hard materials such as marble and granite. They are used in various construction and rehabilitation applications. Its design allows for clean and precise holes.

Dry Cut

Dry-cut diamond crowns are used in situations where water cooling is not required. They are ideal for moisture-wicking materials, such as ceramic. Its use allows for effective drilling, avoiding the generation of excess mud.

Wet Cutting

Wet cutting, on the other hand, uses water to cool the tool and minimize dust production. This type of crown is preferred when working with natural stone, as water also improves the quality of the cut. The use of water helps extend the life of the tool and offers cleaner finishes.

Diamond Blades

Diamond blades are one of the most versatile tools for polishing and cutting surfaces. They can be used on a variety of machines and are suitable for both mining and construction. Its design and composition vary to suit different jobs.

Granulometries and Sizes

These discs are available in a wide range of grain sizes, which determine the degree of roughness or smoothness of the finish. Sizes also vary, allowing them to be used in different machines. Choosing the right grain size and size is essential to achieve the desired finish.

Wet & Dry Use

Diamond blades can be used dry or wet, depending on the application and material in question. Dry use results in faster work, while wet use allows for a better finish and minimizes dust generation. This flexibility makes diamond blades essential in polishing projects.

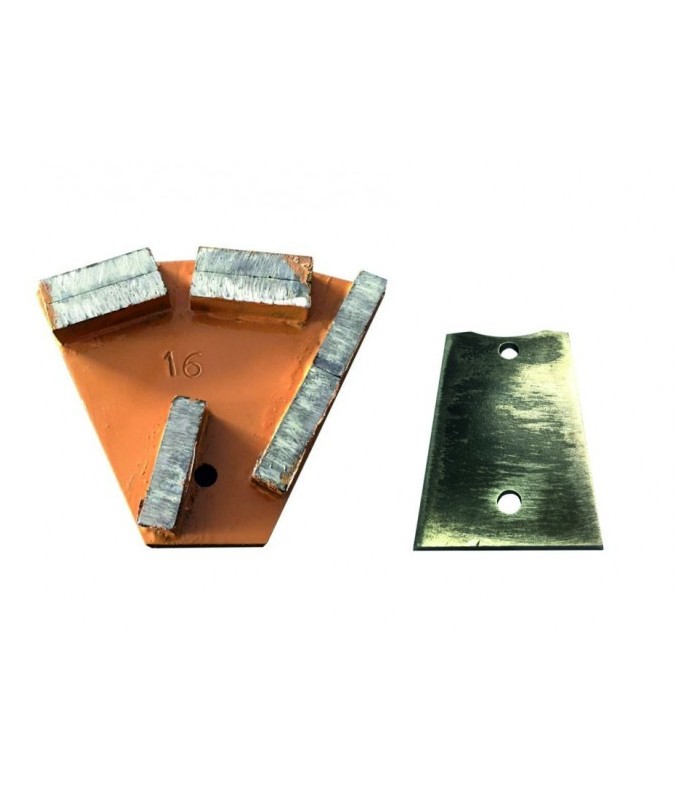

Diamond Segments

Diamond segments are commonly used in grinding and grinding machines. They are manufactured to deliver optimal performance in various conditions and are essential in the construction industry.

Variability in the Number of Segments

The number of segments in each tool may vary depending on the needs of the job. A higher number of segments generally translates into a finer finish, while fewer segments can be useful for shredding harder materials quickly.

Common Applications

These segments are used in a variety of applications, such as the initial roughing of a surface or the final finishing in delicate jobs. Choosing the right segment is crucial to ensure that the end result meets quality expectations.

Putties and peroxides

Although they are not diamond tools in themselves, mastics and peroxides play an important role in the treatment and restoration of surfaces. They are used to fill imperfections and provide a glossy finish to materials such as marble and granite.

Uses in Marble and Granite

Caulks are ideal for repairing cracks and other damage to marble and granite surfaces. This not only improves the aesthetics of the surface, but also contributes to its durability. Peroxides, on the other hand, are used to obtain a brighter finish, acting as bleaching agents.

Application Techniques

The correct application of putties and peroxides is essential to achieve a professional finish. These products must be mentioned, applied precisely and under the right conditions to ensure optimal results. The application technique can include sanding and subsequent polishing, ensuring that the treated surface blends harmoniously with the environment.

Applications of diamond tools

Diamond tools have a wide range of applications in various sectors. Their ability to offer high-quality finishes makes them an indispensable resource in multiple areas, from construction to surface rehabilitation.

Construction

In the construction industry, diamond tools are essential for cutting and polishing hard materials. They are commonly used for:

- Make precise cuts in the marbles and granites used in the manufacture of countertops, floors and facades.

- Facilitate the installation of decorative elements, such as pillars and mosaics, by ensuring a perfect finish without imperfections.

- Allow the creation of holes in stone using diamond crowns, ensuring that the process is carried out cleanly and efficiently.

Surface Rehabilitation

The rehabilitation of damaged surfaces is another key application of diamond tools. In this context, they are used to:

- Restore worn or stained floors by polishing the surfaces, restoring them to their original shine.

- Removing scratches and deep marks from the slabs, achieving a uniform and renewed appearance.

- Apply specific treatments that include putties and peroxides to eliminate imperfections until optimal finishes are achieved.

Commercial Facilities

Commercial environments, where aesthetics and durability are critical, also benefit from the use of diamond tools. Its applications in this area include:

- The installation of flooring in shops and restaurants, where a high traffic resistance finish is required.

- The maintenance of surfaces in places of high influx, ensuring that they remain impeccable and attractive to customers.

- The use of polishing techniques that allow a prolonged shine to be obtained, improving the presentation of the products on sale.

Finishing Work

In finishing work, diamond tools are essential to achieve flawless surfaces. Its applications include:

- The Porcelain Stone Grinding Plant is a highlighter of marble and granite, obtaining shiny surfaces that highlight the natural beauty of the materials.

- The creation of decorative finishes in terrazzo, which combine different elements to achieve unique and personalized designs.

- The optimization of roughing and final finishing processes, allowing a more agile and efficient workflow.

Techniques for using diamond tools

The proper use of diamond tools is essential to achieve optimal polishing on various surfaces. Below are the essential techniques to maximize the performance of these tools during the polishing process.

Surface Preparation

Before starting polishing, it is crucial to properly prepare the surface to be worked on. This involves several steps:

- Surface inspection: Check the condition of the surface to identify damage or imperfections that need to be pre-treated.

- Thorough cleaning: Ensure that the surface is free of dust, dirt and debris. This prevents particles from interfering with the polishing process.

- Necessary repairs: If cracks or wear are observed, they should be repaired before starting polishing. Caulk or peroxide can be used to seal and restore damaged areas.

Selecting the Right Tool

Choosing the right diamond tool is crucial. This depends on the material to be polished and the desired finish. Some aspects to consider are:

- Type of material: Identify the type of stone (marble, granite or terrazzo) to select the appropriate blade or crown.

- Granulometry: Choose the granulometry according to the degree of finish required. Finer grits offer a smoother finish.

- Compatibility: Ensure that the chosen tool is compatible with the machine available for use.

Water Use During Polishing

The use of water is recommended during marble and granite polishing, as it provides multiple benefits:

- Cooling: Prevents overheating of the tool and surface, prolonging tool life.

- Dust reduction: Decreases the amount of dust generated during the process, creating a cleaner work environment.

- Improved finish: Helps achieve a smoother, shinier finish, as water acts as a lubricant.

Proper Movement

The movement made during polishing directly influences the result. Some recommendations include:

- Uniform movements: Apply the tool with stable and constant movements to ensure a homogeneous polish.

- Avoid excessive pressure: Do not put too much pressure on the tool; This can lead to uneven wear or damage to the surface.

- Change of direction: Alternate polishing directions to avoid marks and finish with a uniform finish.

Finishing the Polishing

Once the polishing process is complete, it is important to carry out a few actions to ensure that the job is properly completed:

- Cleaning debris: Remove any residue or excess material with a damp cloth or a specific vacuum cleaner for dust.

- Final Inspection: Examine the surface to make sure there are no marks or areas that need additional touch-ups.

- Applying Finishes: If required, apply finishing products to improve the gloss and protection of the treated surface.

Diamond Tool Innovations

The continuous evolution in the manufacture of diamond tools has brought with it important innovations. These improvements allow not only to increase the efficiency in the use of these tools, but also to expand their functionality and adaptability to the diverse needs of the sector. Below are some of the main innovations in this area.

Diamond Retention Reinforcement

One of the most significant innovations is the advancement in welding techniques that ensure better retention of diamonds on the surface of the tool. This reinforcement translates into:

- Increased durability: Improved welding technology extends tool life, reducing the need for frequent replacements.

- Better Cutting Results: Optimal diamond retention allows for superior performance, resulting in more precise cuts and higher quality finishes.

- Reduced wear: Innovative welding minimizes wear on diamonds, maintaining their efficiency for longer.

Product Customization

The focus on customization is booming among diamond tool manufacturers. This development involves:

- Adjust according to specific needs: Industry professionals can request tools that are tailored to specific requirements, such as particular sizes or specific technical characteristics.

- Customized grain options: A variety of diameter granulometry is offered, allowing you to select the most suitable one according to the type of material to be processed.

- Compatibility with different machines: Tools can be designed to be compatible with a wide range of existing machinery, improving versatility.

Sustainable Practices

Concern for the environment has led many manufacturers to implement sustainable practices in the production of diamond tools. These include:

- Recyclable materials: Materials that are less harmful to the environment and can be recycled at the end of their useful life are being used.

- Waste reduction: The manufacturing process is optimized to minimize material waste, contributing to a more responsible development.

- Efficient production: Improvements in manufacturing are not only focused on product quality, but also on reducing energy consumption during the production process.

Considerations for Selecting Diamond Tools

The proper selection of diamond tools is essential to ensure optimal results in polishing and surface treatment. A number of factors must be considered that will influence the effectiveness and durability of the chosen tools.

Evaluation of the Material to Be Polished

It is essential to analyze the type of material that is going to be worked on. Each surface has specific characteristics that will determine the most suitable type of diamond tool. Some aspects to take into account are:

- Material Hardness: Knowing the hardness of the surface will help select the necessary grain and type of tool. For example, granite is harder than marble, which requires tools with different characteristics.

- Surface Texture: Texture can influence the type of segment or disc to use. Rough surfaces may require more aggressive tools for initial roughing, while smooth surfaces will require tools for fine polishing.

- Surface Condition: If the surface is damaged or imperfect, tools should be chosen that are capable of making effective repairs and preparing the surface for a proper finish.

Working Conditions

The conditions in which the work will be carried out are another aspect to be evaluated. Factors such as space, machine type, and environment all influence the choice of tools. The following should be considered:

- Workspace: In tight spaces, it may be necessary to opt for more compact tools or those that offer maneuverability without sacrificing power.

- Environment: If conditions are wet or dusty, it will be important to use tools that are adapted to these environments, such as those that allow the use of water during polishing.

- Project Duration: If heavy tool use is anticipated, it is preferable to invest in higher durability options that withstand wear and tear and extend their service life.

Machinery Compatibility

It is crucial to ensure that the diamond tools selected are compatible with the machines that will be used in the polishing process. Factors to consider include:

- Connection Types: Tools must have the right type of connection for the machines to be used, whether in polishers, grinders, or specific polishing systems.

- Machine Power: The power of the machinery used influences the type of tool that can be chosen. Tools must be able to operate effectively with the available power.

- Speed Requirements: Each tool can have an optimal speed range. It is important to ensure that the machinery used is capable of providing these speeds so as not to compromise the performance of the tool and to achieve satisfactory results.

Maintenance and cleaning of diamond tools

Proper maintenance and cleaning of diamond tools are critical to prolonging their life and ensuring optimal performance. Below are best practices for caring for these special tools.

Regular Cleaning

Regular cleaning of diamond tools is essential to avoid accumulations of dust and debris that can affect their performance. It is advisable to follow the following steps:

- Make sure the tool is turned off and unplugged before starting cleaning.

- Use a soft brush or cloth to remove dust and dirt from the surface of the tool.

- If necessary, warm water and mild soap can be used to clean more thoroughly. Avoid using harsh chemicals that could damage the tool.

- Dry the tool thoroughly after cleaning to prevent corrosion.

Proper Storage

Proper storage of diamond tools helps protect them from damage and ensures that they are kept in optimal condition. For adequate storage, the following aspects must be considered:

- Store the tools in a dry place, free of moisture, as moisture can cause rust and deterioration.

- Use specific cases or supports for each tool, preventing them from coming into contact with objects that may cause damage.

- Place the tools in an orderly manner, using spacers if necessary to prevent them from scratching or deteriorating.

- Label cases or containers to facilitate the identification of each tool and its proper use.

Replacement of Worn Tools

With time and continuous use, diamond tools can wear out, affecting their effectiveness. Therefore, it is important to know when it is the right time to replace them. The following points should be considered:

- Regularly inspect tools for signs of wear, such as loss of diamonds or reduced cutting capacity.

- Establish a maintenance plan that includes periodic evaluation of the condition of the tools, facilitating the identification of those that need to be replaced.

- Choose quality tools that present clear indications about their useful life, which will allow better monitoring of their wear.

- Dispose of worn tools responsibly, following proper recycling and disposal guidelines to minimize environmental impact.

Frequently Asked Questions About Diamond Tools for Professional Polishing

Diamond tools are essential in the professional polishing industry. Below are some of the most common questions related to their use and maintenance.

How to choose the right diamond blade?

Selecting the right diamond blade is critical to achieving optimal results in surface polishing. Some factors to consider are:

- Type of material: Depending on whether you are working with marble, granite or terrazzo, you should choose a disc with the appropriate grain size.

- Purpose of the work: It is necessary to consider whether the disc will be used for cutting, roughing or polishing.

- Compatibility: Verify that the disc is compatible with the machine to be used and has the correct diameter.

Is dry or wet polishing better?

Both methods have their advantages and disadvantages. Dry polishing produces less waste and is faster, but generates more dust, which can affect the operator's visibility and health. On the other hand, wet polishing reduces dust and cools the tool, prolonging its life, but it can be more complicated to clean and requires careful handling of water.

What maintenance do diamond tools require?

Proper maintenance ensures that the service life of diamond tools is extended. Maintenance guidelines include:

- Regular cleaning: Remove dust and debris from discs and crowns after each use.

- Visual inspection: Check for visible damage or wear to tools before starting a new job.

- Proper storage: Store tools in a dry and protected place to prevent corrosion and physical damage.

How long do diamond tools last?

The durability of diamond tools depends on several factors such as the type of material being worked on, the polishing technique used and the frequency of use. A diamond blade can last anywhere from several hours to several days of intensive work, while crowns typically have a longer lifespan if used correctly and properly maintained.

Are diamond tools compatible with all polishers?

Not all diamond tools are compatible with all polishers. It is crucial to check the manufacturer's specifications of the tools and machines. Factors such as the diameter of the blade, the type of connection and the clamping system are elements to consider to ensure the correct installation and operation of diamond tools.

Diamond Tools Pricing and Costs

The cost of diamond tools varies considerably depending on a variety of factors. These prices are influenced by the quality, the type of tool and the specific characteristics they present. Below is a detailed analysis of the factors that affect these prices and a comparison according to the type of tool.

Factors Influencing Prices

- Quality of Diamonds: The quality of the diamonds used in the manufacture of the tool is one of the main determinants in its price. Diamonds of higher purity and with better cutting properties usually cost more.

- Type of Tool: The specific type of diamond tool also affects the cost. For example, diamond blades are often priced differently than crowns or segments.

- Size and Granulometry: Larger tools or with specific granulometries may have higher costs due to their greater demand and production technology.

- Brand and Manufacturer: Recognized brands in the diamond tool market often offer products at a premium price, backed by a reputation for quality and durability.

- Technological Innovations: Tools that incorporate the latest innovations, such as diamond retention improvements or customization, tend to have a higher cost due to the technology involved.

- Market Conditions: Market price fluctuation can influence diamond tool costs, as factors such as material availability or demand from the construction industry can affect prices.

Price Comparison by Tool Type

Diamond tool prices can vary depending on their classification. Below is a general comparison that reflects the price ranges that can be found in the market.

- Diamond crowns:

- Dry-cut crowns: between €20 and €60 per unit.

- Wet cutting crowns: generally from €40 to €100 per unit, depending on the diameter and quality.

- Diamond Discs:

- Dry cutting blades: prices ranging from €15 to €50 each.

- Wet polishing discs: these range from €25 to €80, depending on size and specific use.

- Diamond Segments:

- Prices typically range from €30 to €150, depending on the number of segments and their configuration.

- Putties and Peroxides:

- Its cost is usually more affordable, between €10 and €30 per container, depending on the quantity and type of product.

These prices are approximate and may vary depending on the provider, special offers, and market conditions at any given time. It is advisable to conduct a thorough analysis of the available options before making a purchase.